Technical data

-

Application

Applicable

› Pipeline

Areas of application

› Chemical

› Pharmaceutical

› Food

-

Medium

› Gases

› Fluids

› Emulsion

› Sirup

› Suspension

› Granulate material

› Powder

-

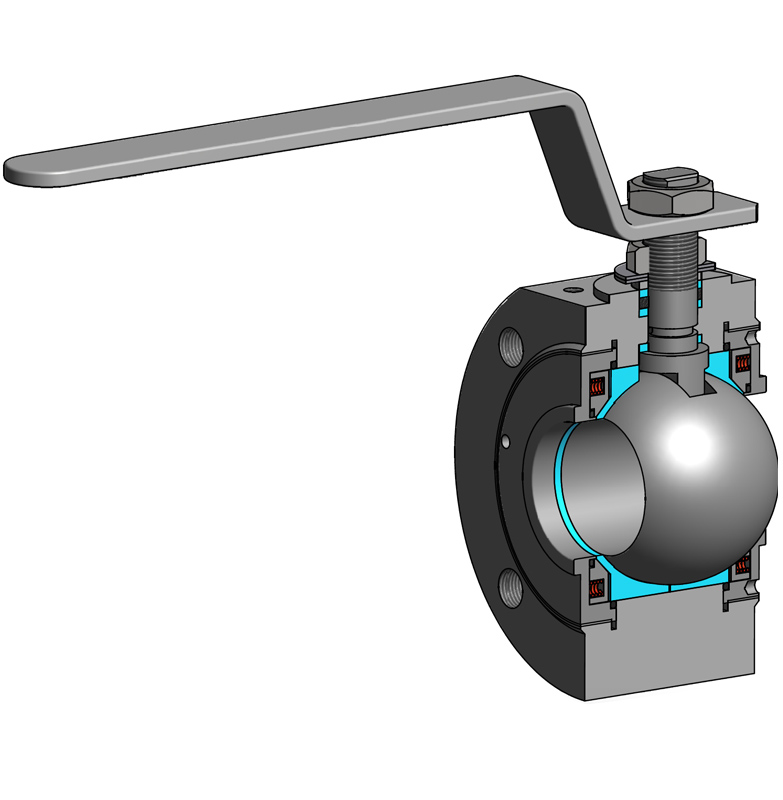

Design

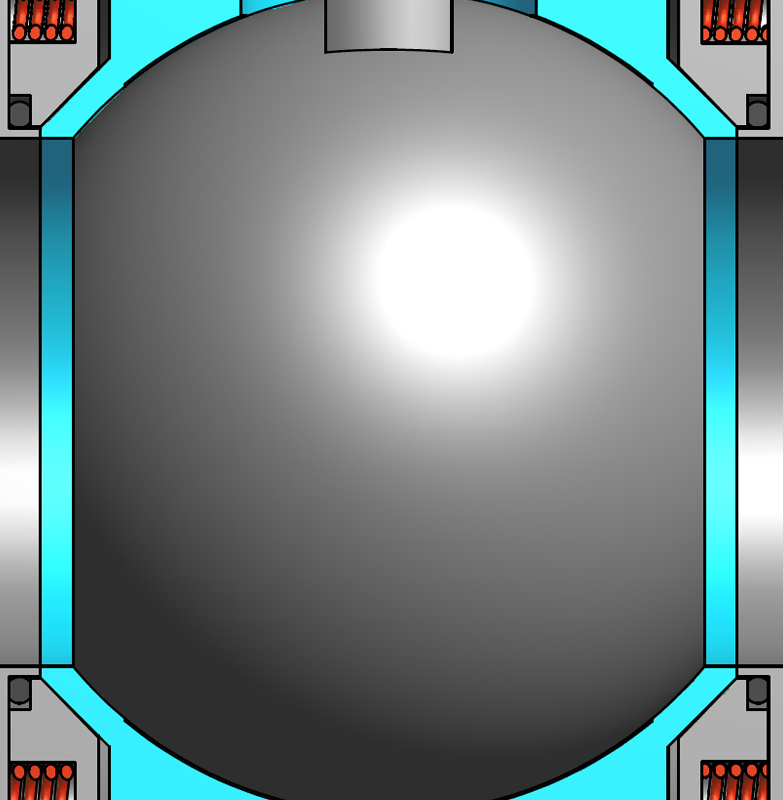

Design

› Cavity free

› Full bore

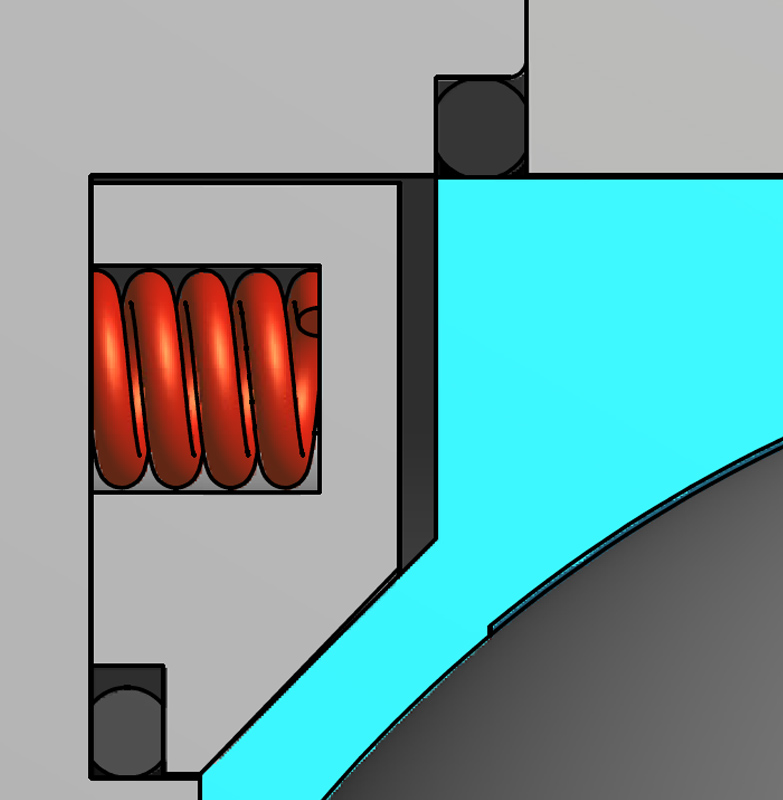

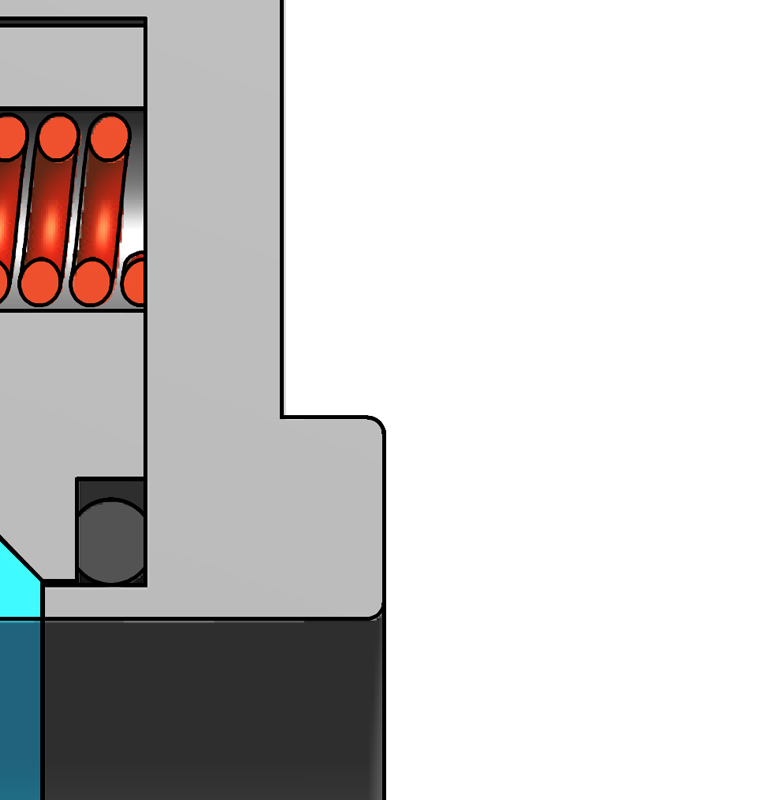

› Spring loaded ball sealing system

› Sealing pressure adjustable by means of spiral coil springs

› Chambered coil springs

› Self adjustable, maintenance free stem sealing with additional o-ring

› blow out proof stem

Additional according to customer requirements:

› Metal to metal sealing system for high pressure, high temperature and abrasive operating conditions

› Heating jacket

› Flushing connection

› Special sizes

› Special face to face length

› Special piping connection

› ANSI connection

› Extended stem

› Double packed stuffing box design

› Antistatic- Design

› Fire Safe Design

› Product wetted surfaces Ra<0,8μm

› Electropolished surfaces

› Oil - and fat free design

› Silicone free design

› Further extras available on request

Connection to pipeline:

› Flange EN1092-1

Tightness test:

› Acc. To EN 12266-1 Leckrate A

Actuator mounting flange:

› DIN/ISO 5211

Certificates:

› TA-Luft

› ATEX 94/9/EG

-

Material

Metal: 1.4404

Ball sealing: PTFE & PTFE/25% Glass fibre

O-Ringe: Viton, EPDM or FEP-Viton

Stem sealing: Packing out of PTFE or pure graphite with additional o-ring

Coil springs: 1.4404

-

Special Material

Metal: austenite stainless steel (904L, 472/649, etc.) nickel- base alloy ( Hastelloy ® B, Hastelloy ® C, C276, Alloy 59 etc.) Duplex , Titanium, Monel ®, Inconel ®, Incoloy ®, Zirconium

Further materials on requestBall sealing: PTFE- Compounds (glass, carbon, graphite, stainless steel, etc.), PEEK, Polyimide, Metal to metal sealing system - High velocity oxygen spraying (HVOF), Flame spraying with additional thermal compaction, Laser deposition welding and Plasma-transferred arc welding (PTA)

Further materials on requestFurther sealing: graphite, FEP coated Compounds, PFA coated Compounds, Kalrez, high- and low temperature - Kalrez, PFA/FEP coated stainless steel for cryogenic application, silver coated metallic o- and c-rings

Conformity: USP, FDA, EFSA, ADI, 3-A, oil- and fat free

Further conformity on requestStem sealing: PTFE chevron packing, high temperature packing

Further materials on requestCoil springs: Hastelloy ®

Further materials on request -

Downloads

Downloads