PHILOSOPHY

Special Ball Valve Manufacturer

The best way to a reliable valve is to customize the valve to the process.

Following this statement, we produce high-end special ball valves according to customer requirements. From the initial inquiry through development and design to installation and testing, the ball valve is adjusted to the customer's requirements and designed for the specific process.

YOUR BENEFIT:

Longer life time

INCREASE IN EFFICIENCY

FAST DELIVERY OF SPARE PARTS

FAST RESPONSE TIME IN CASE OF FAILURES

Especially for extreme applications such as high pressures, high and low temperature, abrasive wear and aggressive products we offer more than 30 years of experience in individual solutions for your projects.

Special materials according to customer requirements.

Specialist in manufacturing valves made of titanium, nickel-based alloys such as Hastelloy ®, Incoloy ®, Inconel ®, Monel ®, Alloy 20, etc., Duplex and many other corrosion-resistant alloys and high-temperature plastics. Through a cooperative relationship with well-known German semi-finished material manufacturers, special materials can be procured in a short time and continue to be processed as quickly as possible.

Fast track delivery

Customer satisfaction is achieved through a high degree of flexibility, since all components are "Made in Germany" and manufactured in-house resulting very short delivery times for special ball valves, repair and spare parts.

Our high flexibility allows fast track delivery e.g. in loss of production.

We deliver worldwide!

Trust our claims

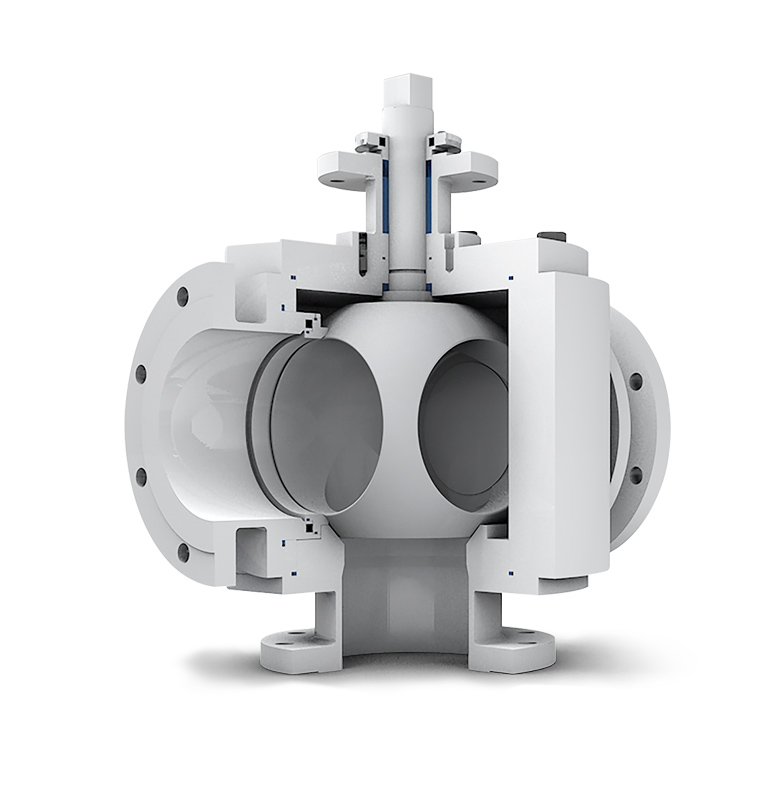

Cavity free ball valves are increasingly important in the chemical, pharmaceutical, cosmetic and food industries, because following arguments must be met:

No dead space between the ball and housing

No residual product in the ball valve housing

Approximately same torque at different temperatures

Longer lifetime through spring loaded sealing system

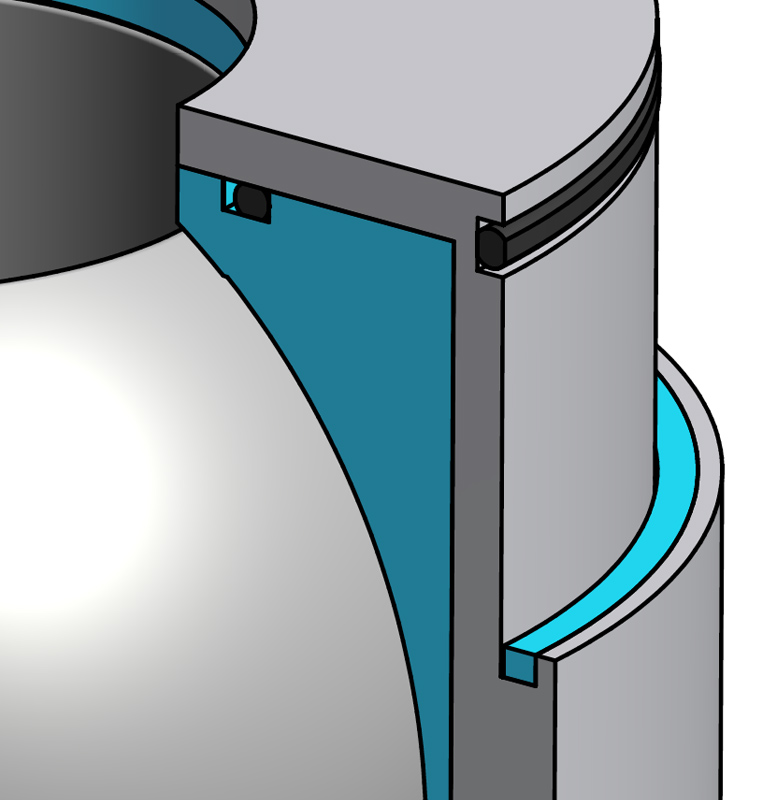

No dead space between the ball and housing

The usual cavity between ball and housing in non- cavity free ball valves give cause for disturbance because residual products can crystallize, polymerize and so affect the function.

No residual product in the ball valve housing

Residual products or rather deposits in dead storage capacity cause contamination e.g. at product change which is for most of the user unacceptable. Furthermore, samples can be falsified.

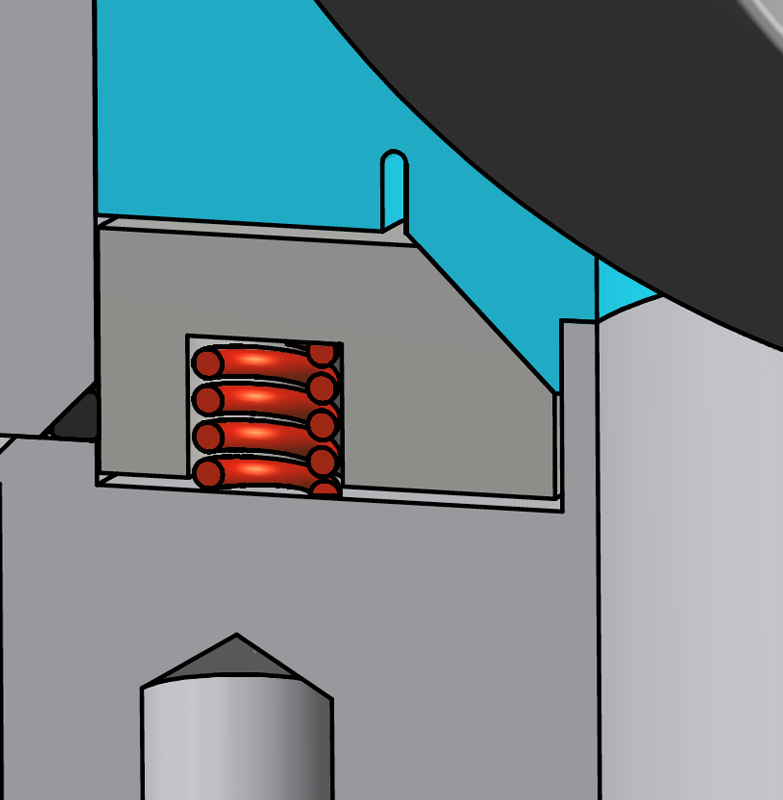

Approximately same torque at different temperatures

This request can only be achieved by ball valves with a spring-loaded sealing system. Different heat expansion of metallic and synthetic material cause high torques by non- spring-loaded sealing systems so that the valve can block and does not open or close anymore.

Longer lifetime through spring- loaded sealing system

Spring-loaded cavity free ball valves achieve this improvement in a variety of processes. At abrasion, the spring-loaded sealing system guarantees a controlled compression of the ball sealing so that longer sealing life and leak-tightness can be realised.

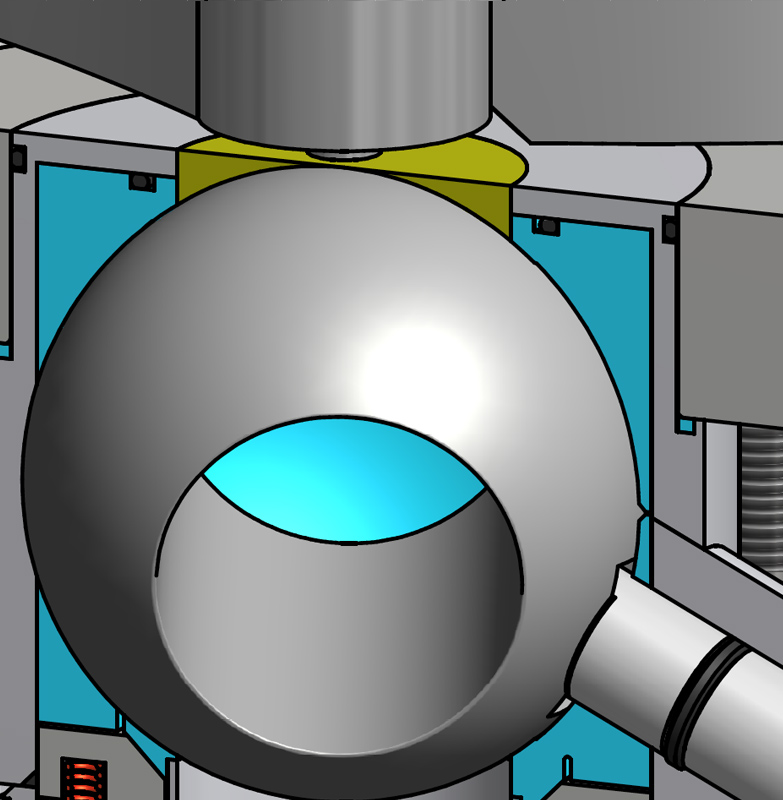

Cavity free ball valve suitable for the use as a sample ball valve and bottom outlet ball valve

To minimize the sump area the balls of ATEC valves are designed in the same height level as the vessel bottom. The short installation length and 90° opening and closing movement are obvious advantages to other bottom outlet valves